Expertise behind intelligent manufacturing,

Shift to Digital Manufacturing Thinking

Transition from "experience-driven" to a systematic "data + model-driven" mindset, with the core being the transformation of business problems into quantifiable, computable, and iterative mathematical problems. This establishes a causal relationship between "production factors → value objectives" through formulas and algorithms.

Smart Manufacturing as Lean Manufacturing

Eliminate non-value-added work: Remove activities in production processes that do not create value.

Improve decision quality: Optimize decisions in production, operations, and other links based on accurate information and analysis to enhance efficiency and benefits.

Enhance the Agility of Supply Chain

Supply chain agility refers to the ability to quickly respond to changes in internal and external environments such as market demand fluctuations and unforeseen supply-side disruptions. The core lies in rapid response and flexible handling of uncertainties, enabling enterprises to maintain competitiveness amid changes.

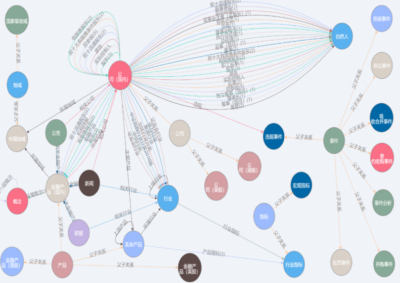

Technical Methodology

Vezu's innovation in Industry 4.0 is reflected in its unique technical methodology. By organizing 5M1E process knowledge into AI-understandable graphs, we train models based on graph data to replace experience-based decision-making and achieve adaptive unmanned execution.

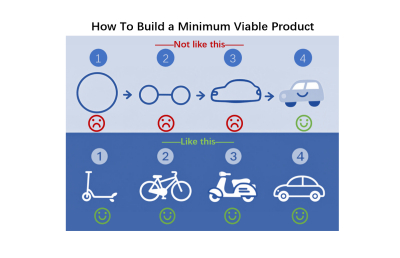

MVP Development Model

A fast and efficient product iteration approach. Build a usable product prototype in the fastest and simplest way to test whether the product meets expectations. Define goals around the core value and establish AI models to ensure continuous optimization of the product during iteration.

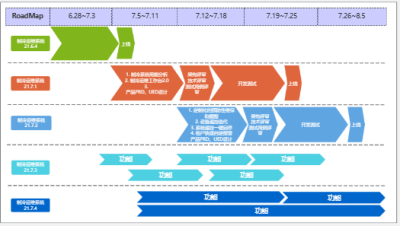

Transformation Roadmap

Vezu has a systematic transformation pathway. Starting with designing an MVP, piloting in a small scope, and gradually promoting after verifying feasibility, we carry out targeted expansion to achieve full coverage of innovation in the entire production system and drive the overall digital transformation of enterprises.

Value Tracking Measurement

Vezu attaches great importance to tracking and measuring innovation outcomes. Through adoption rate and value tracking mechanisms, we quantify the benefits of innovation. For example, in terms of cost savings, specific data on weight savings, labor savings, and energy consumption savings clearly demonstrate the actual value brought to clients by innovation.

Challenges: Complex food safety traceability, large seasonal demand fluctuations, insufficient process stability.

Solutions: AI quality control systems and dynamic scheduling optimization. Ensure compliance through real-time IoT monitoring and blockchain traceability technologies, and optimize key process parameters through digital twins to achieve dual improvements in inventory turnover and production efficiency.

Solutions: AI quality control systems and dynamic scheduling optimization. Ensure compliance through real-time IoT monitoring and blockchain traceability technologies, and optimize key process parameters through digital twins to achieve dual improvements in inventory turnover and production efficiency.

Food Industry

Challenges: Long new drug R&D cycles, strict GMP compliance requirements, and process reliance on experience.

Solutions: R&D-production integrated technology. Ensure compliance through AI automated review and electronic batch record systems, and shorten R&D cycles and improve product quality stability through Bayesian network real-time optimization of process parameters.

Solutions: R&D-production integrated technology. Ensure compliance through AI automated review and electronic batch record systems, and shorten R&D cycles and improve product quality stability through Bayesian network real-time optimization of process parameters.

Pharmaceutical Industry

Challenges: Disconnection between formula R&D and market demand, low multi-SKU changeover efficiency, and pressure for sustainable transformation.

Solutions: Consumer insight-driven new product development via AI, intelligent packaging line changeover using visual recognition systems, and material usage optimization through life cycle analysis to support green production.

Solutions: Consumer insight-driven new product development via AI, intelligent packaging line changeover using visual recognition systems, and material usage optimization through life cycle analysis to support green production.

Daily Chemicals Industry

Challenges: Complex multi-vehicle mixed production scheduling, high supply chain disruption risks, and carbon management pressures.

Solutions: Flexible manufacturing systems and supply chain digital twin simulation. Reduce changeover time through AI dynamic scheduling, optimize global supply chain resilience, and reduce production carbon emissions using carbon efficiency models.

Solutions: Flexible manufacturing systems and supply chain digital twin simulation. Reduce changeover time through AI dynamic scheduling, optimize global supply chain resilience, and reduce production carbon emissions using carbon efficiency models.

Automotive Industry

Challenges: Yield fluctuations, high equipment maintenance costs, and process tuning reliance on experts.

Solutions: AI defect prediction and root cause analysis models, predictive maintenance to reduce unplanned downtime, and knowledge graph-based autonomous optimization of deposition, lithography, and other process parameters to improve yield and overall equipment efficiency.

Solutions: AI defect prediction and root cause analysis models, predictive maintenance to reduce unplanned downtime, and knowledge graph-based autonomous optimization of deposition, lithography, and other process parameters to improve yield and overall equipment efficiency.

Electronics and Semiconductor Industry

Challenges: Process safety risks, raw material price fluctuations, and environmental compliance requirements.

Solutions: Real-time equipment anomaly early warning through multi-sensor fusion models, dynamic procurement strategy optimization integrating futures data, and intelligent control of waste gas treatment systems using mechanism models to ensure production safety and emission compliance.

Solutions: Real-time equipment anomaly early warning through multi-sensor fusion models, dynamic procurement strategy optimization integrating futures data, and intelligent control of waste gas treatment systems using mechanism models to ensure production safety and emission compliance.