Intelligent manufacturing consulting

Smart Energy Solution

Smart energy leverages technologies such as the Internet of Things (IoT), big data, and artificial intelligence to conduct full - dimensional, real - time monitoring and intelligent management of various energy consumptions (water, electricity, gas, heat, etc.) in scenarios like buildings, industries, and parks. Through smart sensing devices, energy consumption data is collected, and combined with algorithmic analysis to uncover energy consumption patterns and waste nodes. This enables dynamic regulation (e.g., optimized equipment start - stop, adjusted load distribution), anomaly warning, and energy efficiency evaluation. It not only helps users accurately reduce energy consumption costs but also drives low - carbon transformation through data - driven energy - saving strategies, providing quantifiable and operable technical support for the implementation of refined energy management.

Smart Energy

Core Pain Points

1. Energy devices (e.g., electric meters, air compressors, HVAC systems) are diverse, lacking unified data collection methods. Severe data silos exist, making it impossible to grasp the real - time overall energy consumption of the entire plant.

2. Manual energy data statistics are inefficient; abnormal leaks and overloads are hard to warn about in a timely manner. Coordinated scheduling of multiple energies like electricity, water, and gas is complex, leading to lagging responses to production fluctuations.

3. Energy - saving strategies rely on manual experience. There’s a lack of AI - driven dynamic energy consumption prediction, root - cause analysis of anomalies, and optimized scheduling, resulting in persistently high energy waste and costs.

4. Data display forms are limited; multi - terminal access is inconvenient, making it difficult to support management’s quick decision - making. The platform has poor scalability, and the development cost of customized energy - saving applications is high.

2. Manual energy data statistics are inefficient; abnormal leaks and overloads are hard to warn about in a timely manner. Coordinated scheduling of multiple energies like electricity, water, and gas is complex, leading to lagging responses to production fluctuations.

3. Energy - saving strategies rely on manual experience. There’s a lack of AI - driven dynamic energy consumption prediction, root - cause analysis of anomalies, and optimized scheduling, resulting in persistently high energy waste and costs.

4. Data display forms are limited; multi - terminal access is inconvenient, making it difficult to support management’s quick decision - making. The platform has poor scalability, and the development cost of customized energy - saving applications is high.

Solution Approach

Smart energy management centers on “full - link digital integration + intelligent closed - loop driving” and progresses in four steps:

Integrate all types of energy devices via the Internet of Things to collect data in real - time and break data silos;

Leverage edge computing and cloud computing to connect data flows, enabling end - to - end management and control to resolve delayed monitoring issues;

The PaaS platform uses low - code tools + AI/knowledge hubs to mine data value, accumulate operational experience, and output dynamically optimized strategies;

The SaaS layer visualizes insights across multiple terminals, converting analytical results into actionable instructions. These instructions trigger coordinated execution and iterative improvement, forming a management closed - loop. This upgrades energy management from “experience - driven” to “data + algorithm - driven”, addressing the needs of cost reduction and efficiency improvement.

Integrate all types of energy devices via the Internet of Things to collect data in real - time and break data silos;

Leverage edge computing and cloud computing to connect data flows, enabling end - to - end management and control to resolve delayed monitoring issues;

The PaaS platform uses low - code tools + AI/knowledge hubs to mine data value, accumulate operational experience, and output dynamically optimized strategies;

The SaaS layer visualizes insights across multiple terminals, converting analytical results into actionable instructions. These instructions trigger coordinated execution and iterative improvement, forming a management closed - loop. This upgrades energy management from “experience - driven” to “data + algorithm - driven”, addressing the needs of cost reduction and efficiency improvement.

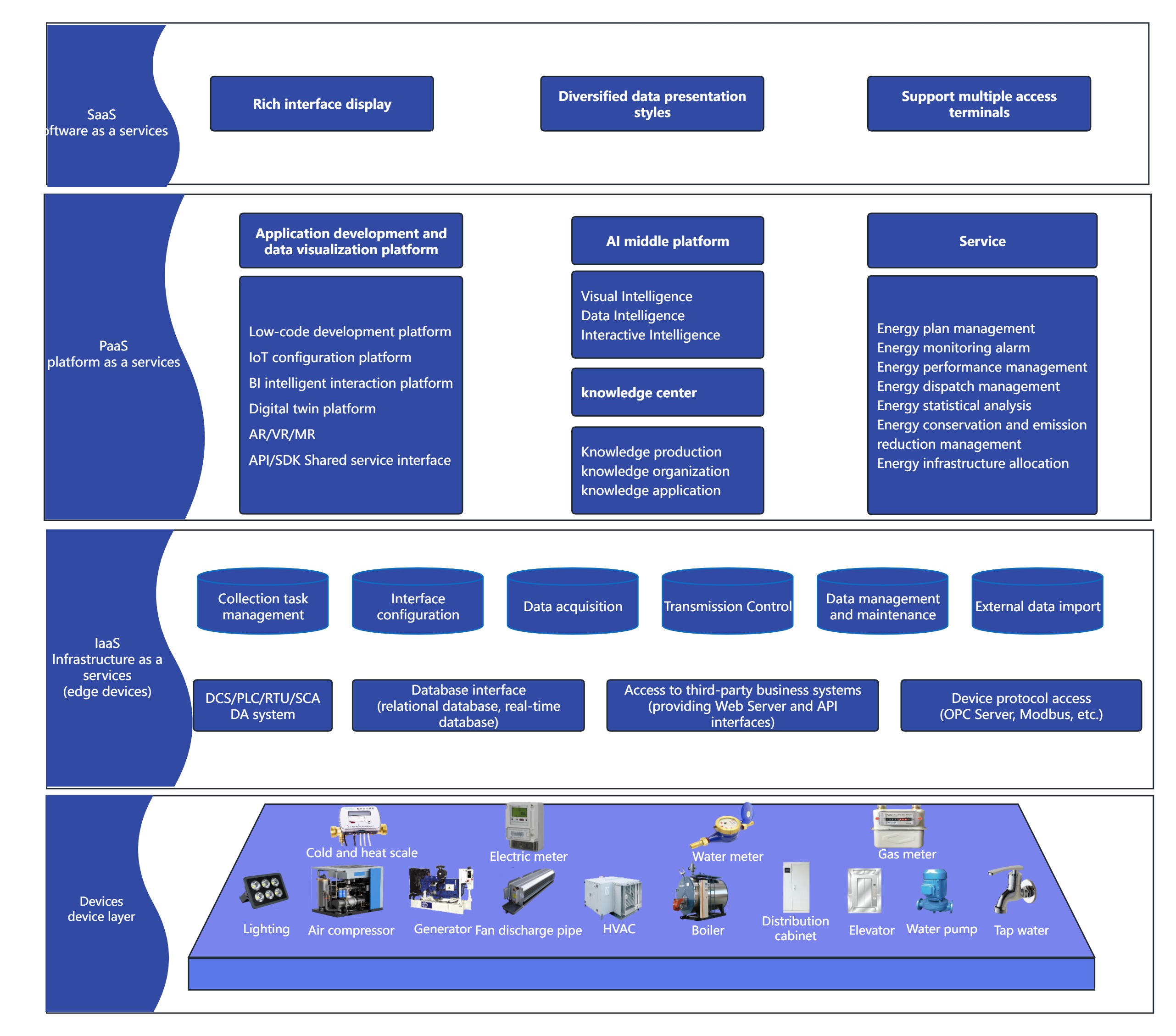

Product Architecture of the Solution

Smart energy management achieves synergy through a four - layer architecture: The device layer connects all types of energy - related equipment; the IaaS layer manages data collection, transmission, and storage to eliminate information gaps; the PaaS layer leverages low - code tools, AI, and a knowledge hub to drive energy consumption optimization; the SaaS layer enables multi - terminal visualization to form a “monitoring - decision - optimization” closed loop. It replaces experiential judgment with data and algorithms to address management pain points.

World class Manufacturing Consulting

Lighthouse Factory Consulting

Solution

Smart Factory Solution

AI Empowered Intelligent Manufacturing Solutions

Agile Supply Chain

Embodied Intelligence Empowers Industry

Smart Warehouse

Information Center

Industry Trends

Intelligent Manufacturing Information

About Vezu

Vezu Introduction

Contact phone number

021-61678386

Email address

info@vezu-ai.com

Company Address

526-528, Building 24, No. 20 Vanke Qibao International, Lane 8633, Zhongchun Road, Minhang District, Shanghai

Shanghai ICP Registration2025124812Number Vezu Pentium Technology (Shanghai) Co., Ltd

Excellent Level Intelligent Factory Consulting

Intelligent Manufacturing Strategic Planning Consulting

Consulting on the Construction of Intelligent Manufacturing Organizations

Smart Energy