Intelligent manufacturing consulting

Smart Warehouse Solution

Smart warehousing is built on a technology foundation of the Internet of Things (IoT), artificial intelligence (AI), and big data. It achieves interconnection among devices such as smart sensors, Automated Guided Vehicle (AGV) robots, and automated storage racks, enabling real - time collection of full - dimensional data including inventory dynamics, storage location status, and operation trajectories.

Powered by the algorithm engine of the Warehouse Management System (WMS), it automatically accomplishes tasks like inbound Stock Keeping Unit (SKU) identification, dynamic storage location allocation, picking path planning, and outbound error - proofing verification, replacing manual experiential decision - making.

From intelligent storage planning for incoming goods, optimal path calculation for picking and distribution, to dynamic monitoring of inventory levels and abnormal warning, it realizes automated flow, intelligent decision - making, and efficient collaboration in warehouse operations.

Smart Warehouse

Core Pain Points

1. Hardware like automated storage and retrieval systems (AS/RS), AGVs, and sorters lacks unified coordination, leading to frequent task conflicts and resource idleness.

2. Storage location allocation, order fulfillment, and task scheduling rely on manual judgment, which is error - prone and slow to respond, failing to match the demands of high - tempo production.

3. Data on inventory status, equipment operation, and task progress is scattered and hard to synchronize timely, causing delayed replenishment, lagging scheduling decisions, and low inventory turnover.

4. When equipment malfunctions or tasks change, there’s no automatic warning or self - healing mechanism, and manual troubleshooting delays production.

2. Storage location allocation, order fulfillment, and task scheduling rely on manual judgment, which is error - prone and slow to respond, failing to match the demands of high - tempo production.

3. Data on inventory status, equipment operation, and task progress is scattered and hard to synchronize timely, causing delayed replenishment, lagging scheduling decisions, and low inventory turnover.

4. When equipment malfunctions or tasks change, there’s no automatic warning or self - healing mechanism, and manual troubleshooting delays production.

Solution Approach

hrough “hardware interconnection → data integration → algorithm - driven scheduling → business closed - loop”, an intelligent system replaces manual decision - making. Data flow breaks coordination barriers, upgrading warehouse operations from “experience - driven” to “data + algorithm - driven”. This precisely resolves pain points like isolated equipment, low efficiency, and delayed decision - making.

Product Architecture of the Solution

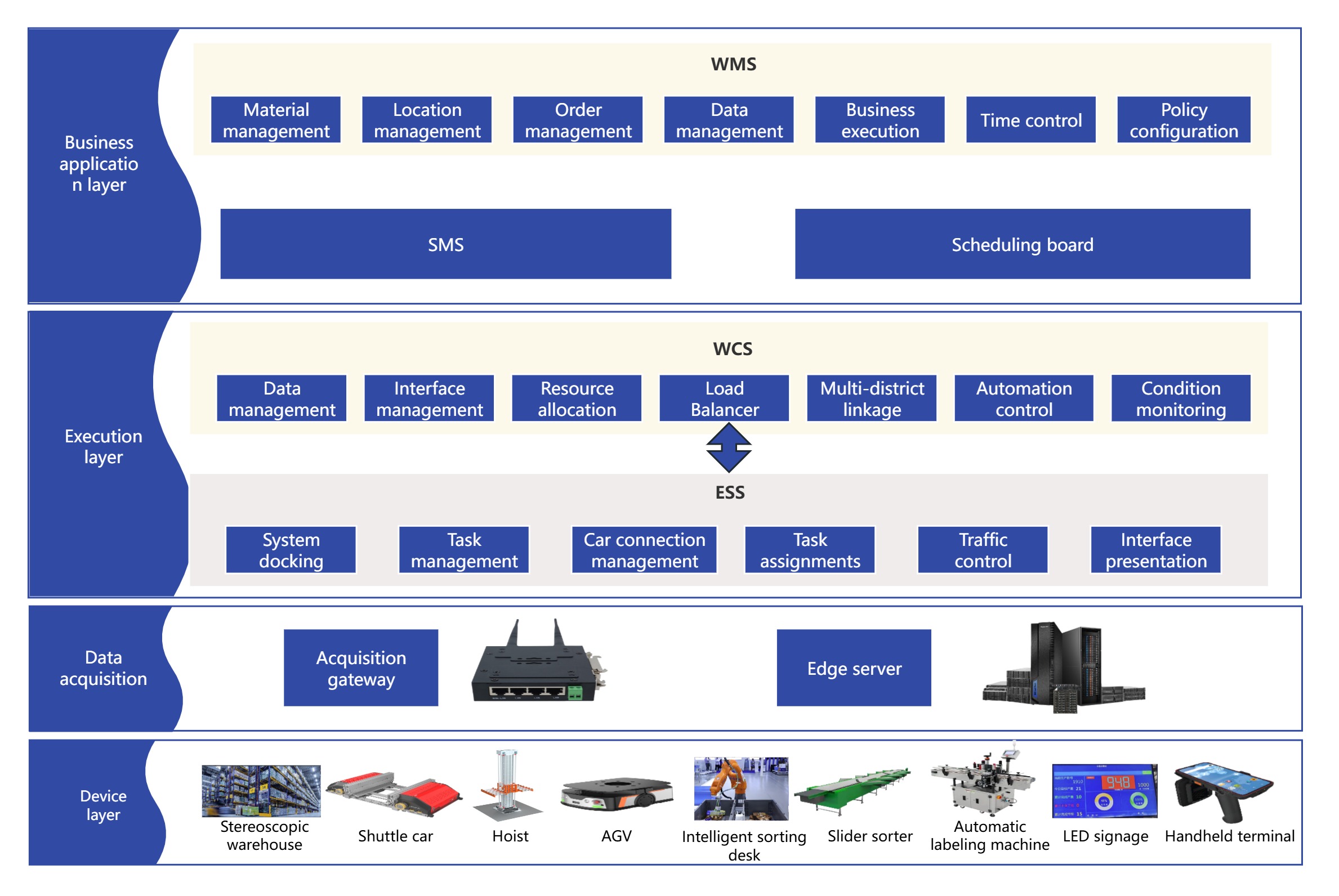

The smart warehousing solution has a four - layer architecture: The device layer connects hardware such as stereoscopic warehouses and AGVs, linked via gateways/edge servers in the data collection layer; the execution layer’s WCS is responsible for resource scheduling and multi - zone linkage, while ESS monitors task and equipment status; the business layer’s WMS coordinates core businesses like materials and orders, with SMS and scheduling dashboards assisting in execution. This achieves hardware interconnection, data integration, and intelligent collaboration.

World class Manufacturing Consulting

Lighthouse Factory Consulting

Solution

Smart Factory Solution

AI Empowered Intelligent Manufacturing Solutions

Agile Supply Chain

Embodied Intelligence Empowers Industry

Smart Warehouse

Information Center

Industry Trends

Intelligent Manufacturing Information

About Vezu

Vezu Introduction

Contact phone number

021-61678386

Email address

info@vezu-ai.com

Company Address

526-528, Building 24, No. 20 Vanke Qibao International, Lane 8633, Zhongchun Road, Minhang District, Shanghai

Shanghai ICP Registration2025124812Number Vezu Pentium Technology (Shanghai) Co., Ltd

Excellent Level Intelligent Factory Consulting

Intelligent Manufacturing Strategic Planning Consulting

Consulting on the Construction of Intelligent Manufacturing Organizations

Smart Energy