智慧仓储

AI-Powered Intelligent Manufacturing Solutions

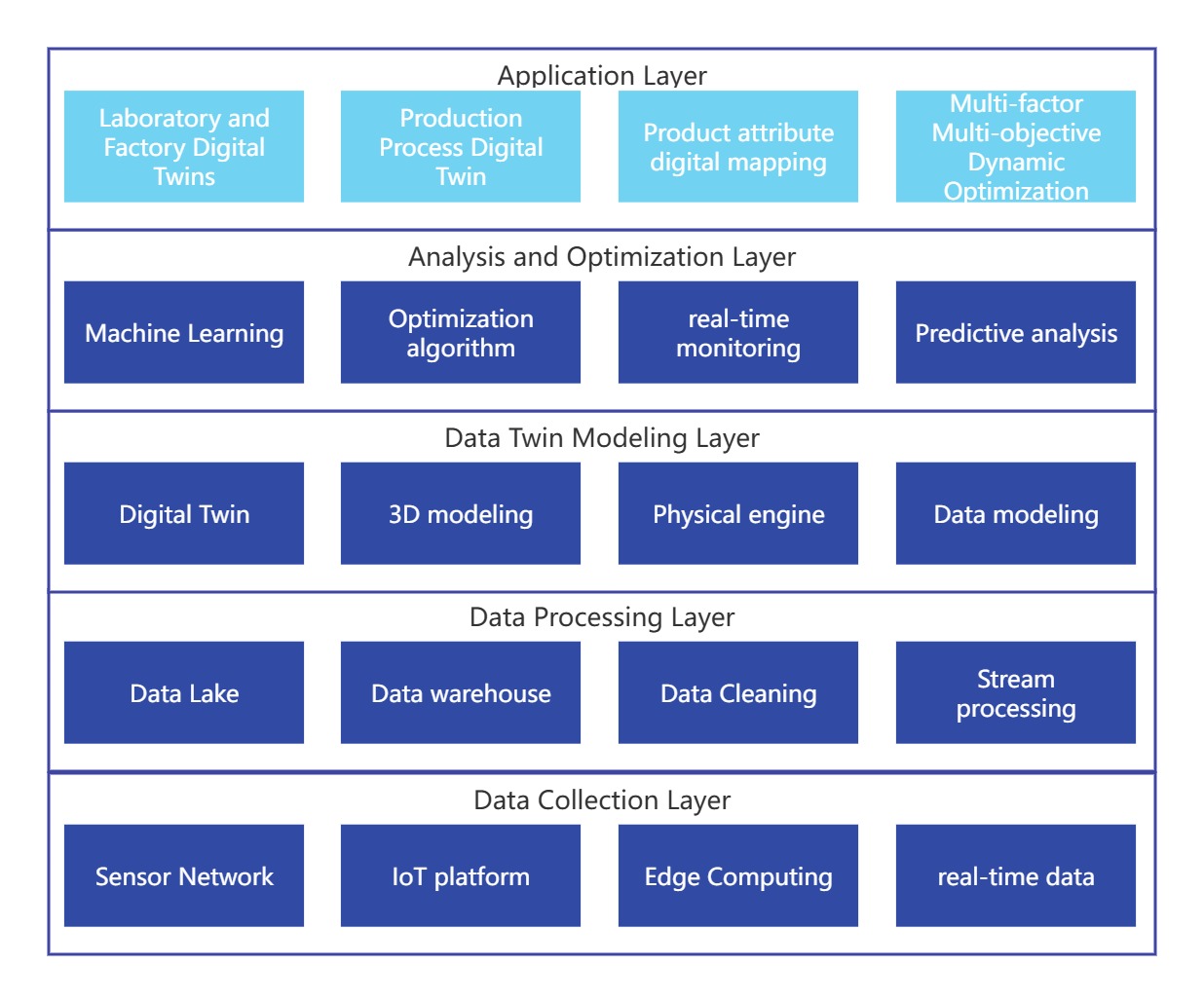

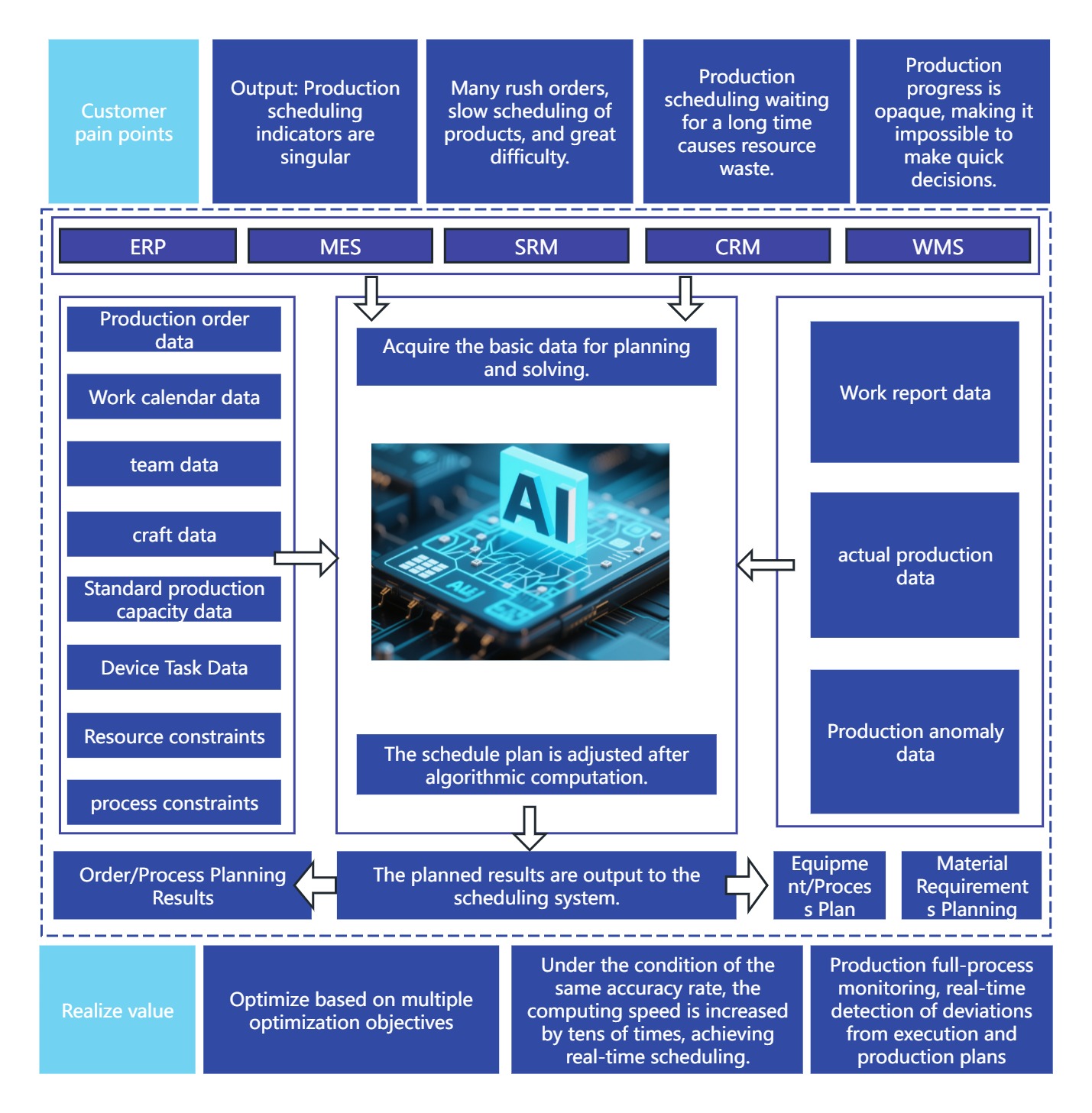

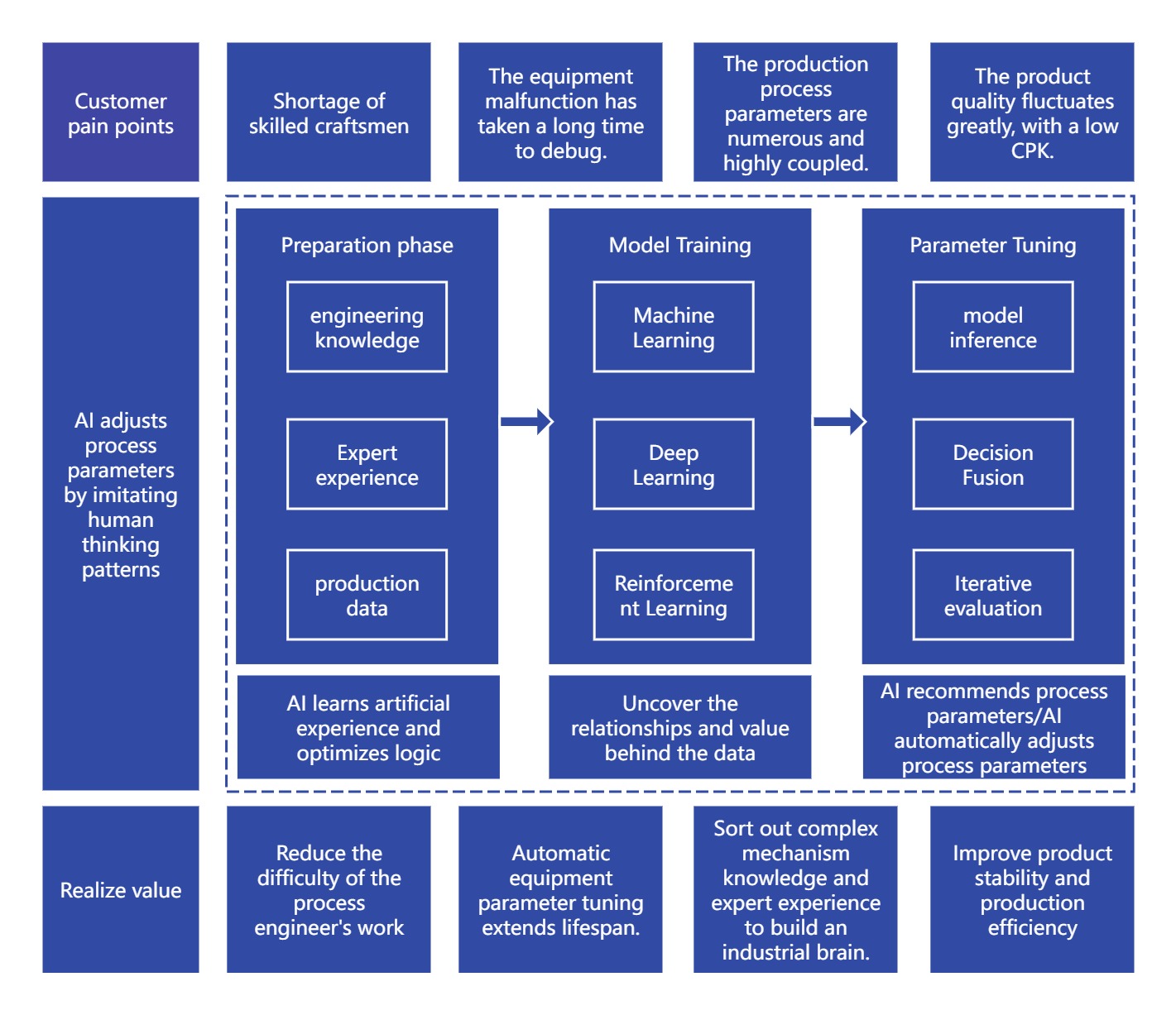

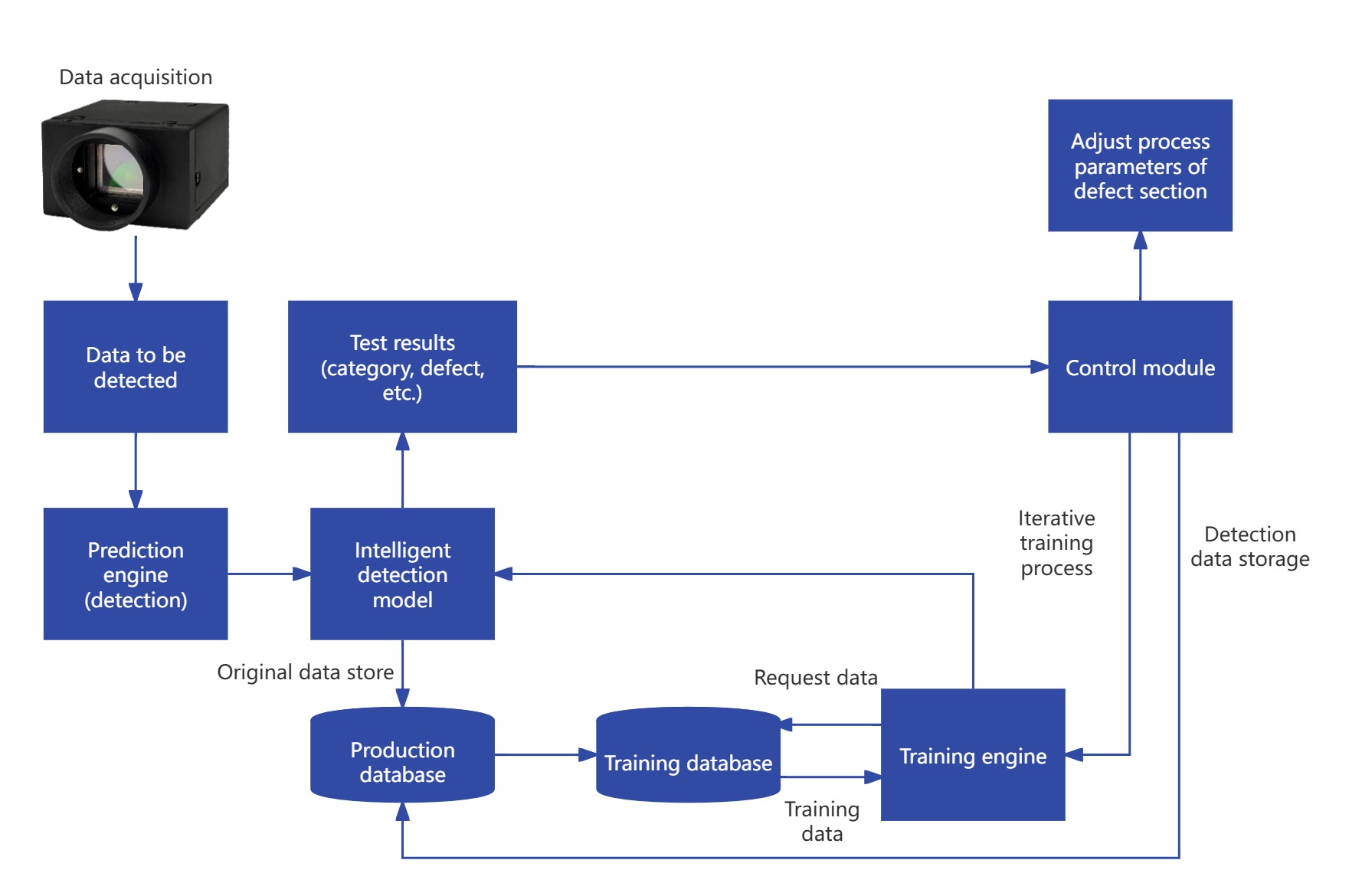

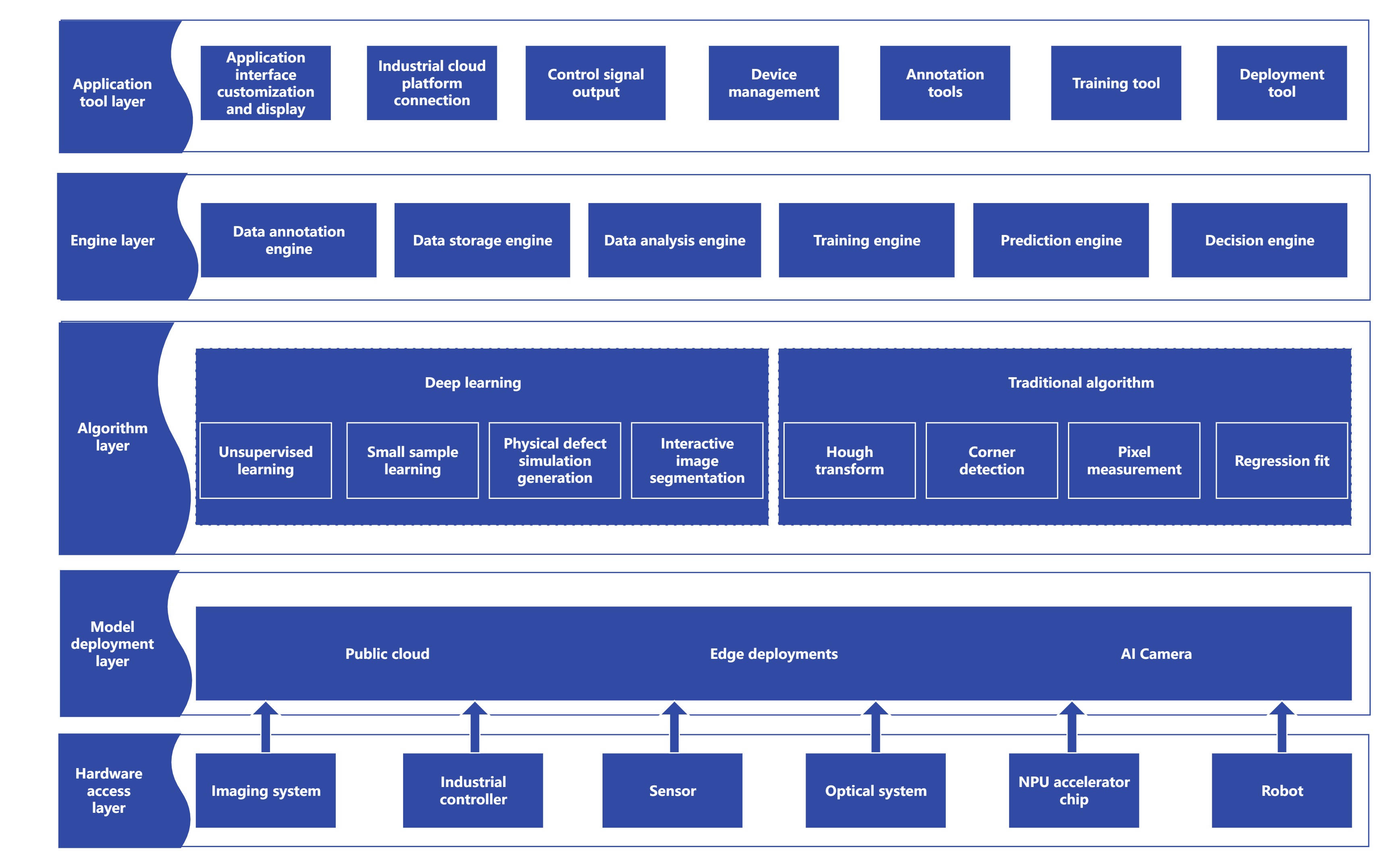

The core of AI-powered intelligent manufacturing is "data-driven decision-making and intelligent process optimization." Enterprises should start with point-specific breakthroughs (e.g., quality inspection, equipment maintenance) and evolve toward full-link intelligence based on their pain points, ultimately achieving the transformation from "manufacturing" to "intelligent manufacturing." Key success factors include: top-level strategic support, data governance capabilities, technical implementation teams, and an agile mechanism for continuous iteration.

Monitoring of Cleaning Actions

Identify whether the cleaning action is performed.

Confirm that the cleaning direction is left - to - right one - way.

Verify if the one - way cleaning consists of 2 passes.

Confirm that the cleaning direction is left - to - right one - way.

Verify if the one - way cleaning consists of 2 passes.

Monitoring of Liquid Preparation Actions

Cameras are deployed at key positions for liquid preparation to recognize key actions in real - time.

Integrated with acid - base testers, image comparison is used to verify if the picking (of materials/reagents) is correct, and it automatically identifies whether the specifications match the operation instructions.

Integrated with acid - base testers, image comparison is used to verify if the picking (of materials/reagents) is correct, and it automatically identifies whether the specifications match the operation instructions.

Monitoring of Assembly Actions

Monitor the entire assembly process in real - time and accurately recognize key actions.

Once abnormal behaviors are detected, immediate warnings are triggered to prompt the production line to respond.

Automatically collect data and generate analysis reports to support management decision - making.

Once abnormal behaviors are detected, immediate warnings are triggered to prompt the production line to respond.

Automatically collect data and generate analysis reports to support management decision - making.

AI Safety Camera Application Scenarios

Personnel Behavior Recognition

Recognition of leaving the post

Smoking recognition

Phone - using recognition

Recognition of personnel falling

Smoking recognition

Phone - using recognition

Recognition of personnel falling

Vehicle Recognition

Unauthorized parking of sedans

Violations by trucks

Forklift violations

Bicycle violations

Violations by trucks

Forklift violations

Bicycle violations

Smart Devices

Equipment status

Anomaly detection

Safety zone

Belt breakage

Anomaly detection

Safety zone

Belt breakage

Safety Attire Recognition

Hard hat recognition

Recognition of skin exposure

Work uniform recognition

Recognition of safety clothing

Recognition of skin exposure

Work uniform recognition

Recognition of safety clothing

Environmental Risk Recognition

Smoke and flame recognition

Recognition of passageway occupancy

Factory Area Safety

Recognition of passageway occupancy

Factory Area Safety

Factory Area Safety

Personnel collision prevention

Perimeter alert

Path guidance

Perimeter alert

Path guidance