Intelligent manufacturing consulting

-

-

Everything QuantifiableConvert business elements (people, machines, materials, methods, environment) into digital signals.

For instance: Worker proficiency → operation error rate; equipment status → vibration frequency data.Goals Decomposable intoMathematical ProblemsStrategic goals form a computable formula network.

Example: Delivery target → deadline = f(process time, equipment failure rate, material availability rate), broken down layer by layer to atomic data nodes.Decisions GeneratedAutomatically by ModelsEstablish a closed loop: "data input → model calculation → intelligent output".

Example: Equipment sensor data inputs a prediction model, which automatically outputs maintenance suggestions. -

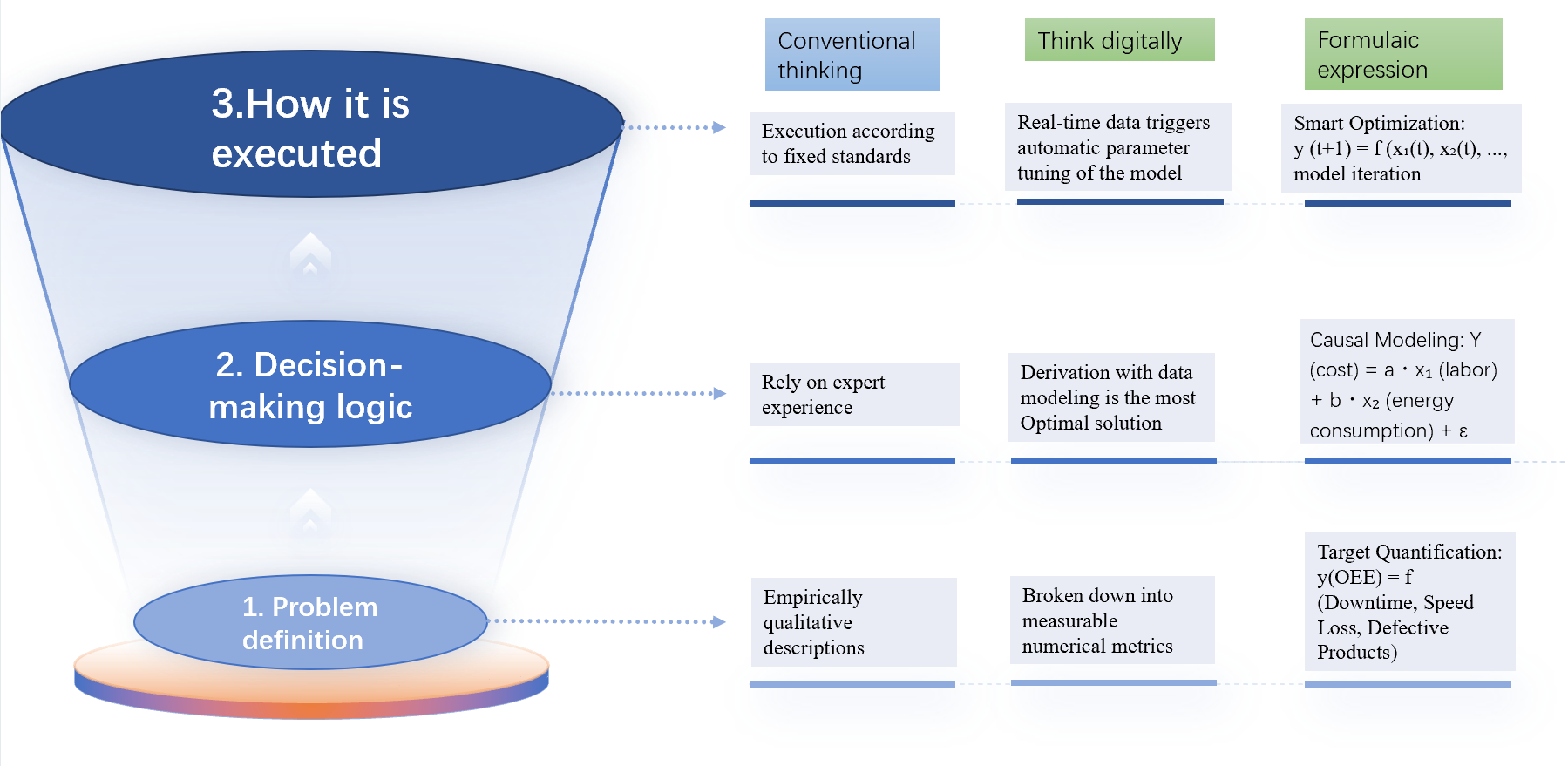

Digitize BusinessProblemsDefine core contradictions using formulas.

For example: High cost → Total cost = Σ (raw material cost + labor cost + energy cost + waste loss).Quantify Data AssetsIdentify variables within formulas.

Example: Deploy sensor systems (x₁–xₙ) to collect data (e.g., install IoT modules on equipment to gather xₙ (energy consumption)).Modelize CausalRelationshipsUse methods like regression analysis and machine learning to fit y = f(x).

Example: Train a "yield rate–temperature" curve model using historical dataAutomate DecisionMechanismsSet model trigger rules.

Example: When the theoretical yield (calculated by formula) < actual yield by 5%, automatically alert and recommend process parameter adjustments.

Embed Digital Thinking in Manufacturing

Digital thinking = Reconstruct business logic using "formulaic language", where each decision is traceable to data variables and model calculations, achieving an intelligent closed loop of "visible problems identified → impacts quantifiable → solutions adjustable".

Smart Manufacturing as Lean Manufacturing

Demand Side: Proactive Variability Forecasting and Mitigation

Proactively reshape supply chain architecture to adapt to dynamic changes.

Use advanced analytics to accurately sense market demand signals.

Apply demand-shaping strategies to guide consumption expectations, optimize labor and process automation planning, and reduce human delays and response lags.

Structural Side: Building Institutional Agility

Enhance supply chain resilience through postponement manufacturing and modular design.

Strengthen cross-departmental collaboration and integrated planning to break down information silos.

Build flexible labor forces through automation and skills upgrading, and create asset flexibility to adapt to multi-category production.

Locate closer to customers to shorten response distances; leverage third-party logistics to enhance distribution flexibility, dynamically adjust manufacturing allocation, and optimize resource deployment.

Strengthen cross-departmental collaboration and integrated planning to break down information silos.

Build flexible labor forces through automation and skills upgrading, and create asset flexibility to adapt to multi-category production.

Locate closer to customers to shorten response distances; leverage third-party logistics to enhance distribution flexibility, dynamically adjust manufacturing allocation, and optimize resource deployment.

Operational Side: Real-Time Response

Deploy end-to-end autonomous planning systems for intelligent decision-making.

Dynamically optimize inventory through digital twins, activate control towers for real-time monitoring, and proactively respond to supply chain fluctuations.

Advance factory digitization to improve operational transparency; optimize freight capacity to reduce logistics costs; form agile teams to quickly address emergencies.